A CQI strategy should be adopted to provide you with a road map toward improvement of your supply chain activities. It should be designed in such a way that takes your retail brand through the process of data collection, data analysis and a continuous cycle of monitoring of activities for efficiency.In this blog post, we take a look at one of our very own retailers that experienced various supply chain complications, and what we did to help them implement an effective CQI plan that would ultimately reduce their expenses and optimise their quality systems.

A well known European sourcing company kept finding that 60% or more of their inspection reports failed or were declared pending. As a quality director you will know that a high pending rating slows down your decision making process and directly affects productivity rates. It was at this point the retailer decided to review the problem in a lot more detail; through the services of a third-party quality provider – API.

So, what was API’s approach?

What was the problem?

One of the top reasons for pending products was a discrepancy in information that was found on the shipping mark compared to that of the product specifications.

But, why were these problems experienced?

The retailer had three different coding systems, which made it difficult for the supplier and they often mixed these numbers up.

API was able to find this problem through various stages of data collection and analysis. API then presented their finding to the management team where it was discussed how to deal with these different coding systems, and what kinds of things should be present on the shipping mark in order to minimise their current supplier confusion.

What solution was implemented?

API was able to identify an opportunity for improvement within the rules and guidelines of the retailer, and the documents were modified to help minimise their suppliers’ confusion. An opportunity was also identified to update the supplier manual to be inclusive of these new modifications, which then needed to be re-distributed to all of the existing suppliers.

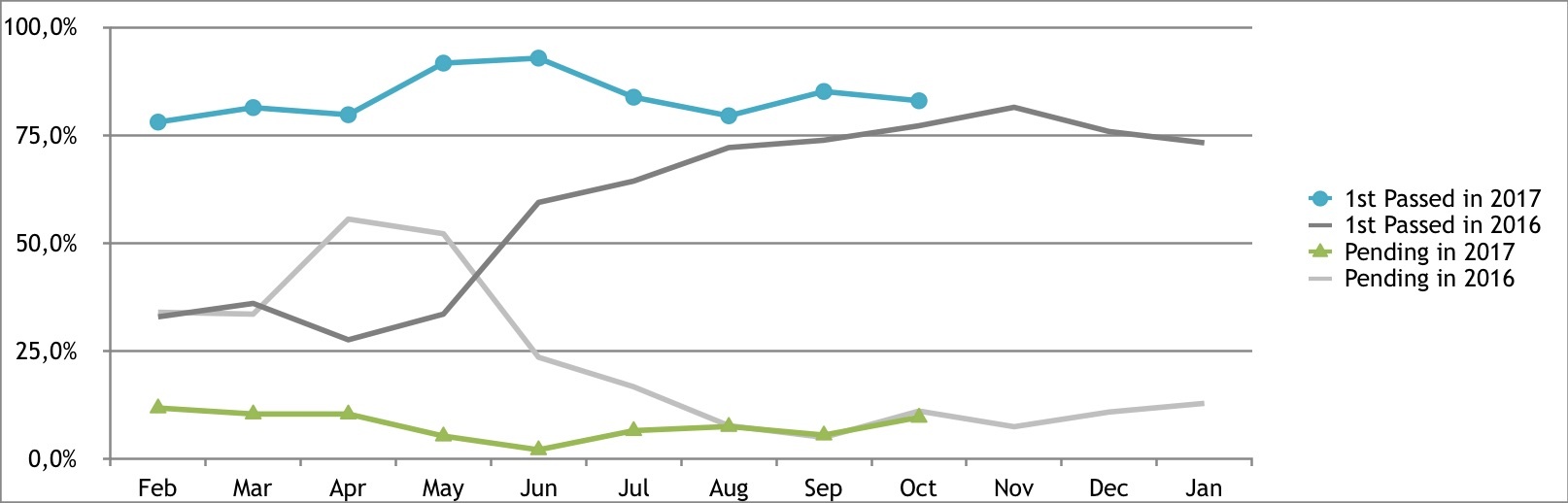

As a part of the continuous quality improvement plan it was strongly suggested to consistently monitor the company’s passing, fail and pending rates in order to effectively evaluate levels of improvement as a direct result of the implementation of the plan suggested by API.

The retailer experienced great success by implementing this solution. They experienced a passing rate that remained mostly over 80% even during peak season.

After the improvement suggestions were implemented it helped this retailer to significantly reduce their pending and failure rates. In a situation like this, it’s important to note that even though the problem was not directly related to manufacturing, it still required both the quality and merchandising team to implement the changes as suggested by API.

Implementing a a continuous quality improvement strategy for your retail brand is essential for production, quality and management effectiveness – without it you will be firefighting problems all along the way. As a part of your strategy you need to be answering these five questions – if you aren’t go back and make sure that you do:

How did your CQI strategy improve;

1. Your organisational effectiveness?

2. Your level of customer satisfaction?

3. Your levels of compliance?

4. Your organisational culture?

5. Your organisation’s documentation?

If you cannot answer those questions definitively you may need to reevaluate your strategy to be more inclusive of addressing them.

Let us know in the comments section below about how you have gone about improving your own quality systems

Want to know more about one of our many services? Contact us to find out more information about what API can do for your company today.

Address

Copyright © 1981 – 2022 API. All Rights Reserved.