Supply chain managers often read supply chain news and yearly trends in order to remain competitive and to determine how they can implement best practices. As we analyze these trends we often look towards global brands and to the way in which they manage their supply chains to achieve their goals. It can be hard and expensive for larger companies and organizations to quickly implement new strategies and adopt new processes in order to stay on top.

To remain globally competitive there are particular strategies that are implemented to achieve those successes. In this blog post, we look at what supply chain solutions can be used to create more transparency, collaboration, and efficiency.

Supply Chain Management Challenges

Supply chain managers face a host of challenges and pressures to constantly keep up with all the moving and evolving parts. Here we list three of the biggest challenges that brands currently face that without being able to manage these effectively can have detrimental effects for you and your brand.- Managing Suppliers – As a supply chain manager you are responsible for knowing all there is to know about your suppliers, from how many suppliers you have to how many are needed specific to your brand. As with any supplier-related problems you need to be able to handle delays, this goes with the territory. Every interaction you have with the supplier needs to be effectively planned thought out in order to create consistency and a smooth running procedure.

Check out our comprehensive guide to learn more about implementing a global quality assurance system.

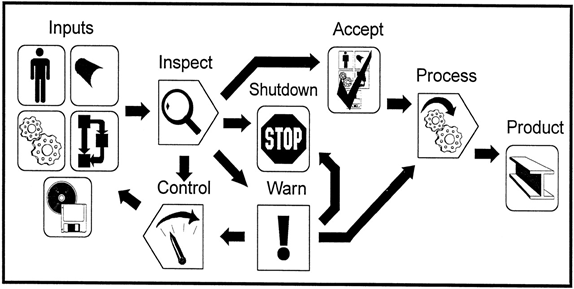

- Risk Mitigation – Adopting a supply chain risk mitigation strategy may be the way to go to avoid the risks that arise. Risk mitigation strategies can include anything from supply chain flexibility to requesting internal supplier related processes to ensure all systems, procedures, and potential risks may be flagged with ample time to rectify if needs are.

If we take a look at Targets mistake of launching the toddler sized Barbie SUV country-wide, the problem they faced was that their distribution centers were receiving inventory faster than they were distributing it to stores across the country. This meant that there were Target stores that had empty shelves with none of the promised items in store. They attributed this to inconsistencies between actual inventory and the computer records. A mistake like this will have cost millions in revenue loss, but also detrimental to both Target and Barbie. As a supply chain manager, it is up to you to ensure you suppliers and distribution centers operate on the same system to mitigate risks like this occurring.

If we take a look at Targets mistake of launching the toddler sized Barbie SUV country-wide, the problem they faced was that their distribution centers were receiving inventory faster than they were distributing it to stores across the country. This meant that there were Target stores that had empty shelves with none of the promised items in store. They attributed this to inconsistencies between actual inventory and the computer records. A mistake like this will have cost millions in revenue loss, but also detrimental to both Target and Barbie. As a supply chain manager, it is up to you to ensure you suppliers and distribution centers operate on the same system to mitigate risks like this occurring.

- Supplier relationship management– (SRM) works on a set of processes that drive consistent, clear interactions between the supplier and buyer, SRM programs build new capabilities that enable strategic sourcing and procurement to make the most of the supplier relationships. Effectively applying SRM as a part of your strategy can help achieve greater quality in your product, faster time to market and results for your bottom line, this owing to the successful implementation of an SRM system.

- Management Inventory – Managing inventory is all about balance, always ensuring you have enough inventory on hand to be able to account for any unforeseen delays so that you do not go “out of stock”. On the other hand, you also do not want to have too much inventory, whether your product is perishable or your product goes out of style, a mismanaged inventory can have vast implications for both brand and supplier. Therefore an efficient inventory control system is crucial.

A team that is led by someone who has a strong sense of leadership can drive the team towards the finish line in a successful manner and ensure that they are achieving the supply chain goals. A strong leader needs to be able to ensure that everyone is on track to achieving the goals as set out. They need to build confidence within the team.

The leader is also responsible for managing all relationships and removing any issues that may hinder the effective functioning of the team. Lastly, the team needs to see you in the trenches, alongside them, digging deep. This creates a sense of solidarity and unity with your team.

“Which business leaders do you look up to? Let me know in the comments below…”

A team that is led by someone who has a strong sense of leadership can drive the team towards the finish line in a successful manner and ensure that they are achieving the supply chain goals. A strong leader needs to be able to ensure that everyone is on track to achieving the goals as set out. They need to build confidence within the team.

The leader is also responsible for managing all relationships and removing any issues that may hinder the effective functioning of the team. Lastly, the team needs to see you in the trenches, alongside them, digging deep. This creates a sense of solidarity and unity with your team.

“Which business leaders do you look up to? Let me know in the comments below…”

Regular, daily reports are important for tracking team progress. The data collected and presented in your weekly meetings should align with your quality control plan and should make recommendations and adjustments where necessary. This will help you and your team understand what goals are on track to being achieved, what problems may need to be addressed and what things need a more strategic focus.

The more accurate and concise your reporting is, the more focused your quality team can be in fixing potential problems and even avoiding potential risks. If your supply chain key performance indicators are not aligned with all departments of your

Regular, daily reports are important for tracking team progress. The data collected and presented in your weekly meetings should align with your quality control plan and should make recommendations and adjustments where necessary. This will help you and your team understand what goals are on track to being achieved, what problems may need to be addressed and what things need a more strategic focus.

The more accurate and concise your reporting is, the more focused your quality team can be in fixing potential problems and even avoiding potential risks. If your supply chain key performance indicators are not aligned with all departments of your  Creating a sense of trust and motivation within your team may sound too emotive for you, but everyone has a desire to be motivated. This creates a sense of ownership and a deeper sense of responsibility and control over their work.

Improved team trust leads to an energized team, an energized team can lead to procedural innovation within your

Creating a sense of trust and motivation within your team may sound too emotive for you, but everyone has a desire to be motivated. This creates a sense of ownership and a deeper sense of responsibility and control over their work.

Improved team trust leads to an energized team, an energized team can lead to procedural innovation within your  Let’s take a dive into some of the historical trends with regards to global sourcing. A brief overview will provide us with why we keep up with these trends and what these trends mean for today. They underpin the way in which we currently view and conduct sourcing, so it is important to understand how sourcing has evolved.

In the early 60’s there was a great focus on purchasing although this was still a clerical based position, as we moved through to the 70’s there was an acknowledgement of the enormity of the task so it became its own department, a department solely focused on purchasing and all the procedures that go into that. As history goes, politics, the environment, and government affect every element of the economy and the manner in which it functions, shifts and changes.

The oil embargo in the late 70’s pushed the agenda of purchasing into the hands of businesses, this made purchasing in the 80’s take a more strategic look into quality, quantity, timing, reliability, and strategy. As I am sure you are aware, the 90’s was all about reducing costs, sometimes at the expense of quality. Although there was also a greater emphasis on developing long-term supplier relationships, with long-term contracts.

This era also birthed good supplier relationship management. The

Let’s take a dive into some of the historical trends with regards to global sourcing. A brief overview will provide us with why we keep up with these trends and what these trends mean for today. They underpin the way in which we currently view and conduct sourcing, so it is important to understand how sourcing has evolved.

In the early 60’s there was a great focus on purchasing although this was still a clerical based position, as we moved through to the 70’s there was an acknowledgement of the enormity of the task so it became its own department, a department solely focused on purchasing and all the procedures that go into that. As history goes, politics, the environment, and government affect every element of the economy and the manner in which it functions, shifts and changes.

The oil embargo in the late 70’s pushed the agenda of purchasing into the hands of businesses, this made purchasing in the 80’s take a more strategic look into quality, quantity, timing, reliability, and strategy. As I am sure you are aware, the 90’s was all about reducing costs, sometimes at the expense of quality. Although there was also a greater emphasis on developing long-term supplier relationships, with long-term contracts.

This era also birthed good supplier relationship management. The  Global sourcing as a whole has made it essential for companies to improve their

Global sourcing as a whole has made it essential for companies to improve their  There is evidence that supply chains are often managed functionally with metrics, systems, and behaviors geared to managing the performance of a specific area. Whilst detailed functional knowledge and understanding are essential to delivering a quality product, a narrow view can lead to a potential misalignment of the different elements of the chain towards the end goal. Senior management needs to ensure that decisions which are taken at the top are not sub-optimised in the operational execution. In practical terms, this means a real transformation in how measurement systems are designed and implemented to ensure that there is a full understanding of how the business interlinks. Individual incentives and success need to be aligned for the achievement of overarching goals, not purely functional excellence.

There is evidence that supply chains are often managed functionally with metrics, systems, and behaviors geared to managing the performance of a specific area. Whilst detailed functional knowledge and understanding are essential to delivering a quality product, a narrow view can lead to a potential misalignment of the different elements of the chain towards the end goal. Senior management needs to ensure that decisions which are taken at the top are not sub-optimised in the operational execution. In practical terms, this means a real transformation in how measurement systems are designed and implemented to ensure that there is a full understanding of how the business interlinks. Individual incentives and success need to be aligned for the achievement of overarching goals, not purely functional excellence.

Be clear – This may sound like an obvious basic principle, but it’s vital to make sure the ‘narrative’ of the information comes across so that it is understood easier and its relevance and context are clear. Use a brief headline, to sum up, the information being communicated and focus on the key aspects of the data as well as why it is important and how it can be used.

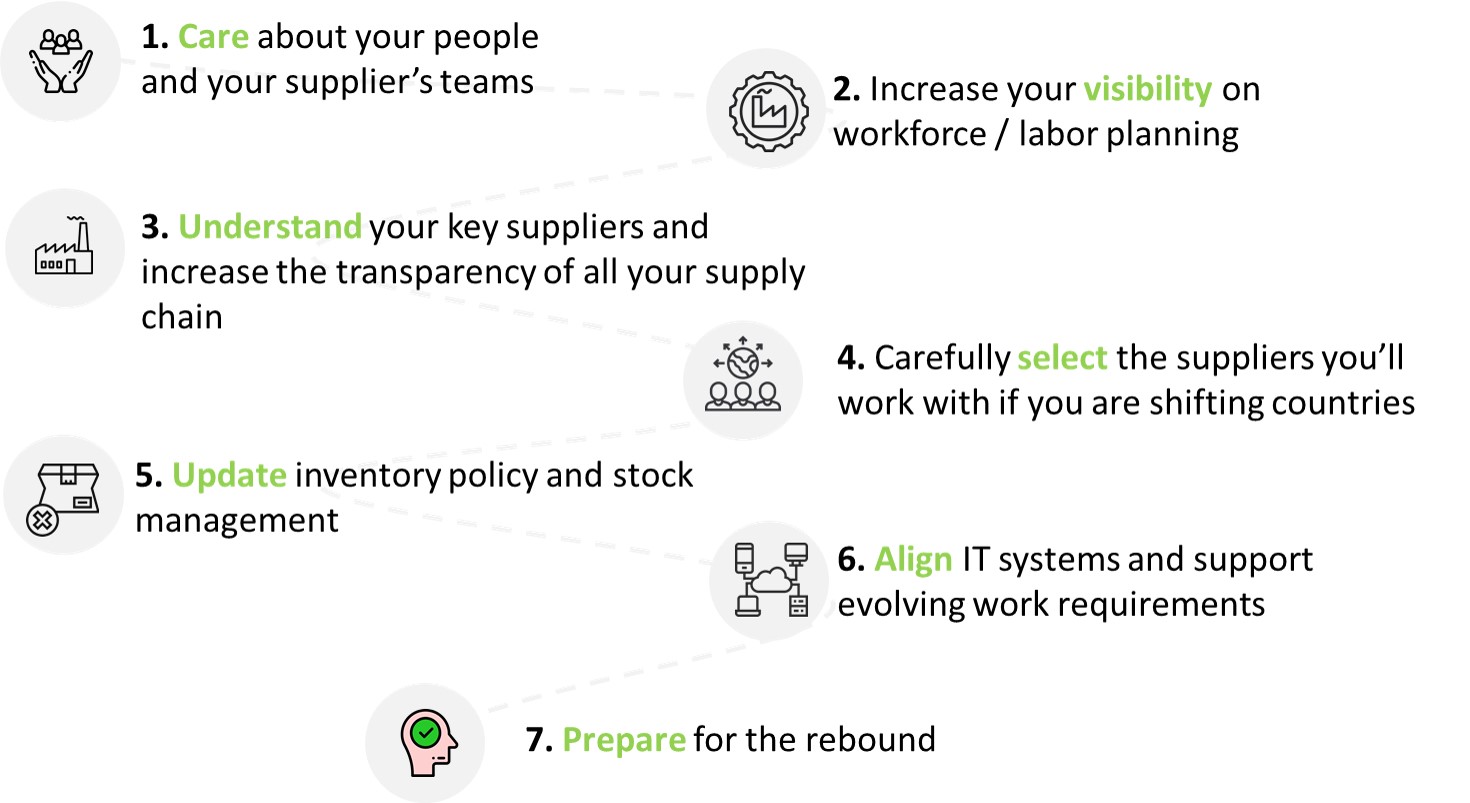

Be clear – This may sound like an obvious basic principle, but it’s vital to make sure the ‘narrative’ of the information comes across so that it is understood easier and its relevance and context are clear. Use a brief headline, to sum up, the information being communicated and focus on the key aspects of the data as well as why it is important and how it can be used. Retailers can protect themselves from potential supply chain interruptions or delays associated with suppliers’ human rights, labor, environmental, and governance practices by ensuring buying offices have effective compliance programs and robust management systems. Here are steps to manage risk:

Retailers can protect themselves from potential supply chain interruptions or delays associated with suppliers’ human rights, labor, environmental, and governance practices by ensuring buying offices have effective compliance programs and robust management systems. Here are steps to manage risk:

Inaccurate data, existing systems infrastructure, and entrenched business practices are common barriers to the implementation of quality management systems. The importance of getting existing processes in line with

Inaccurate data, existing systems infrastructure, and entrenched business practices are common barriers to the implementation of quality management systems. The importance of getting existing processes in line with  Once you have done your best to involve all relevant parties in the quality assurance procedures, your next task is to keep your finger on the pulse.

Once you have done your best to involve all relevant parties in the quality assurance procedures, your next task is to keep your finger on the pulse.

Even if your quality assurance procedures seem to be working fine, and you have integrated QA and open channels of communication, you may still be falling behind.

Best practices are called that for a reason.

They are tried and tested and shown to improve the success of companies. However, they are always progressing, and so should you.

Do get complacent with what you have, or let hubris stand in the way of taking note of what works for others.

Seeing what works for those in a similar field may greatly improve your business, through incorporating useful ideas, tools, or

Even if your quality assurance procedures seem to be working fine, and you have integrated QA and open channels of communication, you may still be falling behind.

Best practices are called that for a reason.

They are tried and tested and shown to improve the success of companies. However, they are always progressing, and so should you.

Do get complacent with what you have, or let hubris stand in the way of taking note of what works for others.

Seeing what works for those in a similar field may greatly improve your business, through incorporating useful ideas, tools, or  All along I have emphasized that QA procedures are a team effort.

You do not have the time to meet with everyone, answer all emails, and be everywhere at once. You also desire time off.

The good news…

You do not need to do everything on your own!

You can pick your battles to optimize expenditure of time and money.

When you do not have the requisite expertise, hiring a 3rd party company may be the way to go.

This could free up time and some responsibility, allowing you to focus more on what you can manage. This will allow for all-round

All along I have emphasized that QA procedures are a team effort.

You do not have the time to meet with everyone, answer all emails, and be everywhere at once. You also desire time off.

The good news…

You do not need to do everything on your own!

You can pick your battles to optimize expenditure of time and money.

When you do not have the requisite expertise, hiring a 3rd party company may be the way to go.

This could free up time and some responsibility, allowing you to focus more on what you can manage. This will allow for all-round  With these five (

With these five (

Effectively managing growing supply chain complexities is something that most purchasing managers/importers deal with on a day to day basis.

As your brand grows compliance issues you never knew were there (nor were prepared for) may rear their ugly head, and it’s up to you to begin pinpointing issues and plugging the holes your profits will fall through, before the consumers of today tear them open even wider.

Ensuring product compliance starts and ends with one thing:

A robust compliance program.

Effectively managing growing supply chain complexities is something that most purchasing managers/importers deal with on a day to day basis.

As your brand grows compliance issues you never knew were there (nor were prepared for) may rear their ugly head, and it’s up to you to begin pinpointing issues and plugging the holes your profits will fall through, before the consumers of today tear them open even wider.

Ensuring product compliance starts and ends with one thing:

A robust compliance program.

purchase price of $69.38 each, resulting in revenues totaling

purchase price of $69.38 each, resulting in revenues totaling  A: One of greatest challenges is ensuring that each branch is able to comply with the

A: One of greatest challenges is ensuring that each branch is able to comply with the  international regulation?

international regulation?