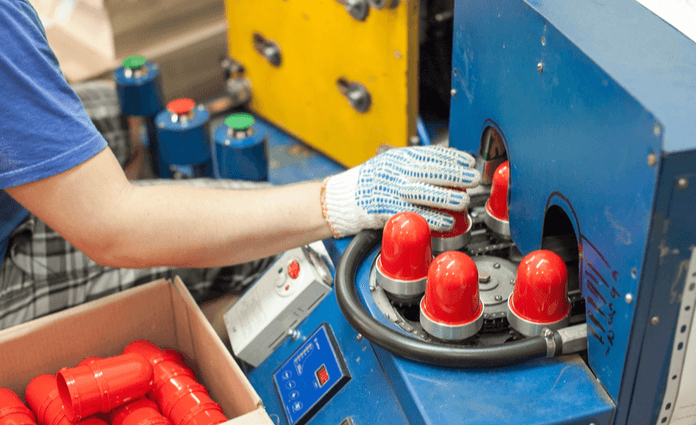

So you want to import DIY tools into Europe, you’ve sourced your supplier in Ningbo, China where you place an order for a shipment of a variety of DIY tools like hammers, star and flat screwdrivers as well as 8 meter tape measures. Your shipment arrives, but your hammer handles are the wrong color and the color of the flat and star screwdrivers are swapped around.If you have had these kind of experiences with quality that is below standard or defect rates that you just can’t seem to reduce, you may need to consider establishing a golden sample from your supplier to eliminate any unnecessary areas of risk.

Why?

Sourcing abroad is a challenge. As a means of overcoming this challenge, we recommend establishing a golden sample which is deemed industry best practice. Along with your golden sample you should consider the use of a third-party quality provider to ensure the quality of your sample is of the highest quality.

Why are golden samples important for improved product quality?

A golden sample allows you to evaluate the quality of product that your chosen supplier can produce.

This process gives you a baseline for how you will continue with your supplier. It will showcase how they interpret your product specifications and how they can stick to them.

**Insiders Tip

Have you communicated your product specs clearly?

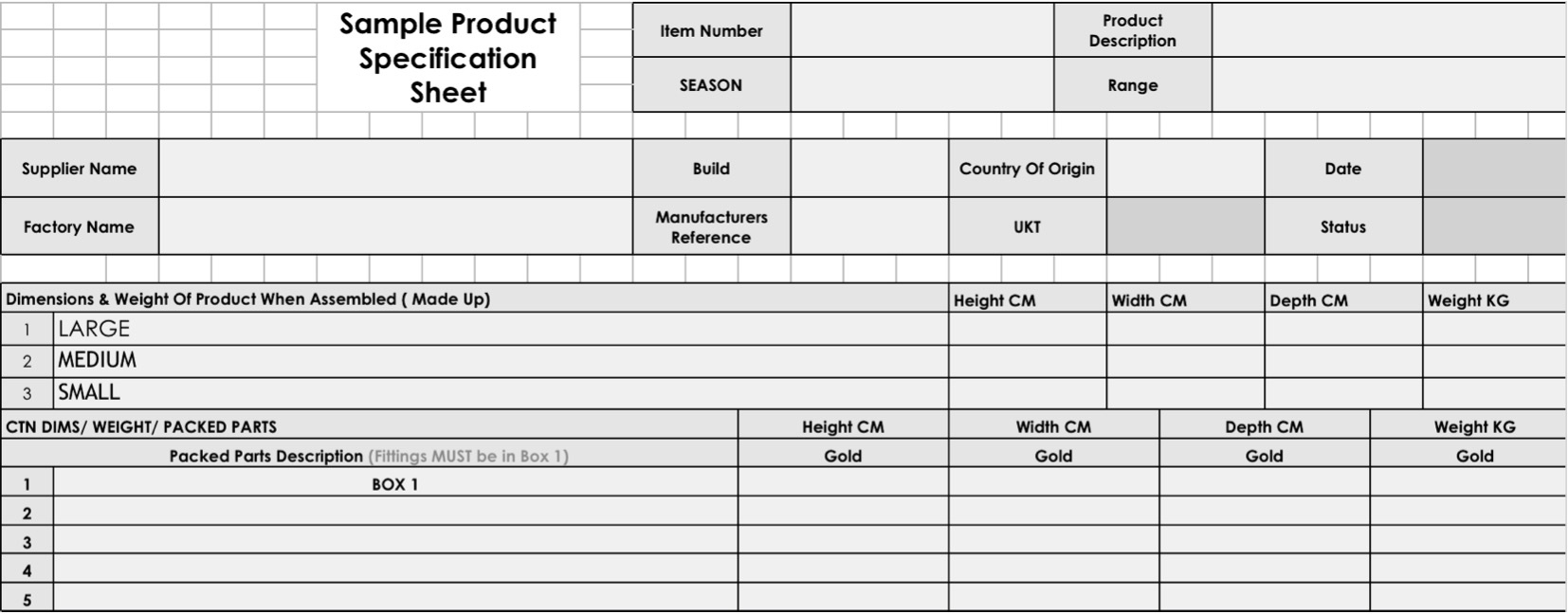

Product specifications can be sent to your supplier in the form of drawings, sketches or images with the correct dimensions and color specifications. A hammer will have a particular color handle, the same with the screwdrivers, so be sure to mention this in your spec sheet.

There is no such thing as too much. Add everything to minimize any confusion.

Why?

You are up against cultural, language and distance barriers, so be as specific as you possibly can be.

Once you have received your golden sample from your supplier, you will need to evaluate whether the quality level is acceptable or not. Once you approve this, you can then give your DIY tool supplier the go-ahead for mass production.

What goes into approving a golden sample for DIY tools?

You need to make sure that your golden sample has met all product specifications along with the necessary compliance standards and regulations.

How do you go about this?

As you would normally do with production…

By inspection.

Your golden sample can be inspected for any visible defects; you can also send it off to a lab for corrosion and chemical testing.

The corrosion test commonly used according to ISO 9227:2017;

Neutral salt spray (NSS) – useful for detecting discontinuities, such as pores and other defects, in certain metallic, organic, anodic oxide and conversion coatings.

The type of chemical tests commonly used for plastic handles;

Polycyclic Aromatic Hydrocarbons (PAH) – Is a harmful carcinogenic. A consumer can be exposed when a product comes into direct and prolonged or repetitive contact with the skin or the mouth. High doses of this substance can lead to recalls like the below product;

Short chain chlorinated paraffins (SCCPs) – SCCP’s persist in the environment and are toxic to aquatic organisms at low concentrations and bioaccumulate in wildlife and humans, posing a risk to human health and the environment. The below hammer handle contains SCCP’s (A banned substance) as well as PAH and has therefore resulted in a recall of the below hammer;

There are three common testing types to ensure improved product quality for your DIY tools like;

- User testing; this kind of testing evaluates the ergonomics of the tools that have been produced. This evaluation will be based on your product specifications and the overall purpose of the product; e.g., A hammer to hammer nails into walls, so the handle length, grip, and head will be evaluated accordingly. An example of this would be the below axe in which the handle can crack after use, which dislodges the axe head, which poses a serious injury risk to the user or even bystanders.

- Comparative testing can also be done. This test is done to evaluate yours against a competitor’s. The functionality, safety, and ergonomics will be evaluated. This kind of test will give you insight into the kind of quality your brand should be achieving.

- Hardness testing – While this is not a testing requirement, this measurement forms an objective criteria for either the metal or plastic components of the item. For example; the hardness of the metal part of a hammer could affect the performance and durability of the product likewise the plastic could affect the feeling when holding the handle of the product.=

Therefore golden samples are not only used to evaluate acceptable quality limits for your DIY tools factory.

What do I mean?

A golden sample will be of huge value for your third-party quality inspection service provider so that they can compare what has been produced through the mass production process to that of the golden sample.

Key Takeaways

Establishing a golden sample is industry best practice, and it is never recommended to begin your mass production process without an approved sample.

This sample allows you to benchmark your supplier and hold them accountable to your acceptable quality levels.

Key things to remember;

- Communicate your product specifications clearly. Bear in mind that you are facing cultural, language and distance barriers, so clarity and over communication is an absolute necessity.

- Approving your golden sample requires due diligence; be sure to send your golden sample for the appropriate inspection and testing.

- Know your testing and inspection procedures to ensure improved product quality for your brand.

Be sure to remember that your golden sample is reflective of an ideal quality standard from your supplier, and is not a reflection on the mass production process of the factory.

This method of reducing product defects for your brand will help avoid costly delays addressing defects after the fact. Adopting best practice sets you in the best possible position for sustainable and competitive growth.

TAKE A DIVE INTO OUR QUALITY INSPECTION GUIDE for IMPROVED PRODUCT QUALITY and reduced defect rates

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

.png)

It is at this point that

It is at this point that A random furniture sample will be selected at this point, where they will each be checked one by one to inspect whether or not they meet the following;

A random furniture sample will be selected at this point, where they will each be checked one by one to inspect whether or not they meet the following;

As a quality manager who is responsible for producing toys you know that where quality is concerned the stakes are sky-high.

You need to know that toys adhere to the demands of every test they might face when being exported globally to markets with different demands.

At API, our quality inspectors and laboratories follow a comprehensive set of 8 toy quality testing steps (built through decades of experience) that helps quality managers effectively manage quality right from the outset.

This article will take a brief look at

As a quality manager who is responsible for producing toys you know that where quality is concerned the stakes are sky-high.

You need to know that toys adhere to the demands of every test they might face when being exported globally to markets with different demands.

At API, our quality inspectors and laboratories follow a comprehensive set of 8 toy quality testing steps (built through decades of experience) that helps quality managers effectively manage quality right from the outset.

This article will take a brief look at  Raw material quality control is paramount in helping to prevent product failure and ensuring a consistent level of quality that you and your customers expect.

Making sure that players in your supply chain are continuously subjected to testing of raw materials being used in your toy production, or when they decide to switch suppliers, verifies that the materials are at the level of quality you’re paying for and that no toxic elements such as lead and cadmium finding their way into your finished product.

Complying with chemical restrictions in raw materials laid out by the EU and US chemical content regulations such as REACH,

Raw material quality control is paramount in helping to prevent product failure and ensuring a consistent level of quality that you and your customers expect.

Making sure that players in your supply chain are continuously subjected to testing of raw materials being used in your toy production, or when they decide to switch suppliers, verifies that the materials are at the level of quality you’re paying for and that no toxic elements such as lead and cadmium finding their way into your finished product.

Complying with chemical restrictions in raw materials laid out by the EU and US chemical content regulations such as REACH,