Christmas, a very special holiday celebrated all around the world, a sacred time spent with family and friends, houses adorned with traditional decorations and illuminated in a splendor of colors, all leading up to the childlike anticipation of Christmas day, the gifts, the food and the wine!

While it may still be quite a few months off for most people, it is now that time of year when suppliers and retailers the world over begin their arduous preparations for the very busy festive season ahead, starting with none other than the hallowed Christmas tree.

In 2015, 12.5 million artificial Christmas trees were purchased in the US alone at a  purchase price of $69.38 each, resulting in revenues totaling $854 million for manufacturers in that short period. As a holiday that approximately 2 billion people around the world celebrate, the market for Christmas and these trees is undeniably massive, not to mention the powerful potential for profits it promises.

purchase price of $69.38 each, resulting in revenues totaling $854 million for manufacturers in that short period. As a holiday that approximately 2 billion people around the world celebrate, the market for Christmas and these trees is undeniably massive, not to mention the powerful potential for profits it promises.

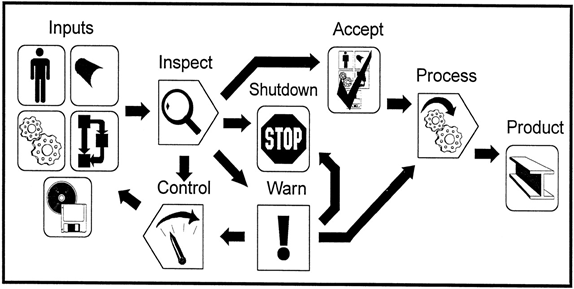

But, what happens when things go wrong on the production line?

Between 2010 and 2014 fire fighters responded to an annual average of 200 homes that were reported to be on fire or burnt down in the US alone due to fires started by Christmas trees with a total damage of $16.2 million. Fires started by malfunctions in artificial trees highlight the critical importance of strict quality control measures needed in place during and after production, from the lighting within the tree, the temperatures they produce to the types of plastic that is used to manufacture the tree.

Can your company stand to lose millions because of negligence in the QC process? What about the implications brought about from families that lose their homes or worse?

Preventing unnecessary damages and losses before they happen should be at the top your Christmas wish list. In this blog post we talk to Francois Deudon, CEO of Asia Pacific Inspection, as we seek to understand the technicalities that go into the making of Christmas trees and the essential QC procedures/tests involved in the production of these products, helping to ensure a safer, happier and more ‘festive’ festive season for us all…

Q: What are some of the challenges involved in the manufacturing of Christmas trees in terms of quality?

A: One of greatest challenges is ensuring that each branch is able to comply with the NFS 54200 / Decree 2003-1123 without any accessible sharp points. In order to comply with this requirement, an industrial practice of bending the end wire of each branch to prevent any accessible sharp points. Many Christmas trees contain hundreds of branches, so the quality control of suppliers plays a significant role so as to manage the potential risks.

A: One of greatest challenges is ensuring that each branch is able to comply with the NFS 54200 / Decree 2003-1123 without any accessible sharp points. In order to comply with this requirement, an industrial practice of bending the end wire of each branch to prevent any accessible sharp points. Many Christmas trees contain hundreds of branches, so the quality control of suppliers plays a significant role so as to manage the potential risks.

Q: One of the biggest concerns that consumers have is the PVC content of an artificial tree – How do quality procedures overcome this kind of challenge?

A: The quality control involved from the design stage to the mass production stage is needed to manage this concern. In the design stage, a client will instruct the supplier that only qualified raw materials should be used to create this product. In the pre-production stage, raw materials or products should be submitted for testing to ensure that these qualified materials are used. Suppliers should not only use these qualified materials; but they should also be able to avoid contamination during the production process. The clients should then assess the chemical management system of the factory, when they choose a supplier. After the production is completed, the client could then appoint a third party company to pick a sample from the mass production for chemical testing to ensure only qualified materials are being used for production and that there is no chemical contamination.

Q: Are suppliers more aware of the raw material and construction of trees that need to comply to strict  international regulation?

international regulation?

A: The more experienced a supplier is the better he will understand the regulations of any given country. Here it will be the retailer or the importer’s responsibility to choose an appropriate supplier. This can be done through a technical audit, which could help measure the capability and capacity of suppliers, providing valuable information when choosing suppliers.

Q: Do you think stricter quality control or inspection measures can help reduce the amount of fires that are started each year due to artificial Christmas trees? How so?

A: Yes, the testing on mass production products will assess the flammability of artificial Christmas trees. It could also avoid unauthorized change of the materials during this mass production process.

Q: What quality tests are absolutely essential before shipping Christmas trees off to various distributors?

A: The flammability test, the sharp point sharp edge test and the REACH test are absolutely essential before shipping to any distributors.

Conclusion

While retailers and importers across the globe are preparing for all the holiday joys, what we have learnt is that it will be important to select the correct supplier, based on previous testing records or it may even be important to consider an audit that will help identify any procedural risks early on, as the scope of the festive season is too big to cut any corners as any faults of failure will have the potential to lose you millions. The various Christmas tree testing procedures will be important to ensuring that the festive season will be a safe and happy one all round.

with efficient quality procedures. They are also up to date with the latest developments in the industry along with the best practices to follow. As a result, you have all the expertise and

with efficient quality procedures. They are also up to date with the latest developments in the industry along with the best practices to follow. As a result, you have all the expertise and

they need products. You may find yourself at a loss with a delivery delay. Contingency plans are essential to ensuring your product gets to market. A

they need products. You may find yourself at a loss with a delivery delay. Contingency plans are essential to ensuring your product gets to market. A  1.Risk Management – Global brands take every procedure into account when understanding possible areas of risk. From sourcing to logistics to inventory management, each of these areas affects one another. If there is a problem with sourcing, it inadvertently affects the logistics of the entire operation. Therefore a brand such as Amazon needs to have a Risk Mitigation strategy that spans the entire operation.

1.Risk Management – Global brands take every procedure into account when understanding possible areas of risk. From sourcing to logistics to inventory management, each of these areas affects one another. If there is a problem with sourcing, it inadvertently affects the logistics of the entire operation. Therefore a brand such as Amazon needs to have a Risk Mitigation strategy that spans the entire operation.

If we take a look at Targets mistake of launching the toddler sized Barbie SUV country-wide, the problem they faced was that their distribution centers were receiving inventory faster than they were distributing it to stores across the country. This meant that there were Target stores that had empty shelves with none of the promised items in store. They attributed this to inconsistencies between actual inventory and the computer records. A mistake like this will have cost millions in revenue loss, but also detrimental to both Target and Barbie. As a supply chain manager, it is up to you to ensure you suppliers and distribution centers operate on the same system to mitigate risks like this occurring.

If we take a look at Targets mistake of launching the toddler sized Barbie SUV country-wide, the problem they faced was that their distribution centers were receiving inventory faster than they were distributing it to stores across the country. This meant that there were Target stores that had empty shelves with none of the promised items in store. They attributed this to inconsistencies between actual inventory and the computer records. A mistake like this will have cost millions in revenue loss, but also detrimental to both Target and Barbie. As a supply chain manager, it is up to you to ensure you suppliers and distribution centers operate on the same system to mitigate risks like this occurring.

Let’s take a dive into some of the historical trends with regards to global sourcing. A brief overview will provide us with why we keep up with these trends and what these trends mean for today. They underpin the way in which we currently view and conduct sourcing, so it is important to understand how sourcing has evolved.

In the early 60’s there was a great focus on purchasing although this was still a clerical based position, as we moved through to the 70’s there was an acknowledgement of the enormity of the task so it became its own department, a department solely focused on purchasing and all the procedures that go into that. As history goes, politics, the environment, and government affect every element of the economy and the manner in which it functions, shifts and changes.

The oil embargo in the late 70’s pushed the agenda of purchasing into the hands of businesses, this made purchasing in the 80’s take a more strategic look into quality, quantity, timing, reliability, and strategy. As I am sure you are aware, the 90’s was all about reducing costs, sometimes at the expense of quality. Although there was also a greater emphasis on developing long-term supplier relationships, with long-term contracts.

This era also birthed good supplier relationship management. The

Let’s take a dive into some of the historical trends with regards to global sourcing. A brief overview will provide us with why we keep up with these trends and what these trends mean for today. They underpin the way in which we currently view and conduct sourcing, so it is important to understand how sourcing has evolved.

In the early 60’s there was a great focus on purchasing although this was still a clerical based position, as we moved through to the 70’s there was an acknowledgement of the enormity of the task so it became its own department, a department solely focused on purchasing and all the procedures that go into that. As history goes, politics, the environment, and government affect every element of the economy and the manner in which it functions, shifts and changes.

The oil embargo in the late 70’s pushed the agenda of purchasing into the hands of businesses, this made purchasing in the 80’s take a more strategic look into quality, quantity, timing, reliability, and strategy. As I am sure you are aware, the 90’s was all about reducing costs, sometimes at the expense of quality. Although there was also a greater emphasis on developing long-term supplier relationships, with long-term contracts.

This era also birthed good supplier relationship management. The  Global sourcing as a whole has made it essential for companies to improve their

Global sourcing as a whole has made it essential for companies to improve their  There is evidence that supply chains are often managed functionally with metrics, systems, and behaviors geared to managing the performance of a specific area. Whilst detailed functional knowledge and understanding are essential to delivering a quality product, a narrow view can lead to a potential misalignment of the different elements of the chain towards the end goal. Senior management needs to ensure that decisions which are taken at the top are not sub-optimised in the operational execution. In practical terms, this means a real transformation in how measurement systems are designed and implemented to ensure that there is a full understanding of how the business interlinks. Individual incentives and success need to be aligned for the achievement of overarching goals, not purely functional excellence.

There is evidence that supply chains are often managed functionally with metrics, systems, and behaviors geared to managing the performance of a specific area. Whilst detailed functional knowledge and understanding are essential to delivering a quality product, a narrow view can lead to a potential misalignment of the different elements of the chain towards the end goal. Senior management needs to ensure that decisions which are taken at the top are not sub-optimised in the operational execution. In practical terms, this means a real transformation in how measurement systems are designed and implemented to ensure that there is a full understanding of how the business interlinks. Individual incentives and success need to be aligned for the achievement of overarching goals, not purely functional excellence.

Be clear – This may sound like an obvious basic principle, but it’s vital to make sure the ‘narrative’ of the information comes across so that it is understood easier and its relevance and context are clear. Use a brief headline, to sum up, the information being communicated and focus on the key aspects of the data as well as why it is important and how it can be used.

Be clear – This may sound like an obvious basic principle, but it’s vital to make sure the ‘narrative’ of the information comes across so that it is understood easier and its relevance and context are clear. Use a brief headline, to sum up, the information being communicated and focus on the key aspects of the data as well as why it is important and how it can be used. Retailers can protect themselves from potential supply chain interruptions or delays associated with suppliers’ human rights, labor, environmental, and governance practices by ensuring buying offices have effective compliance programs and robust management systems. Here are steps to manage risk:

Retailers can protect themselves from potential supply chain interruptions or delays associated with suppliers’ human rights, labor, environmental, and governance practices by ensuring buying offices have effective compliance programs and robust management systems. Here are steps to manage risk:

Inaccurate data, existing systems infrastructure, and entrenched business practices are common barriers to the implementation of quality management systems. The importance of getting existing processes in line with

Inaccurate data, existing systems infrastructure, and entrenched business practices are common barriers to the implementation of quality management systems. The importance of getting existing processes in line with  Once you have done your best to involve all relevant parties in the quality assurance procedures, your next task is to keep your finger on the pulse.

Once you have done your best to involve all relevant parties in the quality assurance procedures, your next task is to keep your finger on the pulse.

Even if your quality assurance procedures seem to be working fine, and you have integrated QA and open channels of communication, you may still be falling behind.

Best practices are called that for a reason.

They are tried and tested and shown to improve the success of companies. However, they are always progressing, and so should you.

Do get complacent with what you have, or let hubris stand in the way of taking note of what works for others.

Seeing what works for those in a similar field may greatly improve your business, through incorporating useful ideas, tools, or

Even if your quality assurance procedures seem to be working fine, and you have integrated QA and open channels of communication, you may still be falling behind.

Best practices are called that for a reason.

They are tried and tested and shown to improve the success of companies. However, they are always progressing, and so should you.

Do get complacent with what you have, or let hubris stand in the way of taking note of what works for others.

Seeing what works for those in a similar field may greatly improve your business, through incorporating useful ideas, tools, or  All along I have emphasized that QA procedures are a team effort.

You do not have the time to meet with everyone, answer all emails, and be everywhere at once. You also desire time off.

The good news…

You do not need to do everything on your own!

You can pick your battles to optimize expenditure of time and money.

When you do not have the requisite expertise, hiring a 3rd party company may be the way to go.

This could free up time and some responsibility, allowing you to focus more on what you can manage. This will allow for all-round

All along I have emphasized that QA procedures are a team effort.

You do not have the time to meet with everyone, answer all emails, and be everywhere at once. You also desire time off.

The good news…

You do not need to do everything on your own!

You can pick your battles to optimize expenditure of time and money.

When you do not have the requisite expertise, hiring a 3rd party company may be the way to go.

This could free up time and some responsibility, allowing you to focus more on what you can manage. This will allow for all-round  With these five (

With these five (

any organizations consider third-party audits for many reasons, mainly they have come to the decision to create a quality management system (QMS) such as ISO 9001. A third-party auditor would come in and assess whether or not this organization meets the requirements as laid out by the above QMS. A third-party auditor will then provide your organization with a certification stipulating that you meet the requirements as laid out. This is often a preferred audit option as the results are unbiased and certification has become a competitive differentiator.

any organizations consider third-party audits for many reasons, mainly they have come to the decision to create a quality management system (QMS) such as ISO 9001. A third-party auditor would come in and assess whether or not this organization meets the requirements as laid out by the above QMS. A third-party auditor will then provide your organization with a certification stipulating that you meet the requirements as laid out. This is often a preferred audit option as the results are unbiased and certification has become a competitive differentiator.