Household goods manufacturing and supply chain operations are often vulnerable to compliance and regulation violations.

With the pace at which the many complex parts of a supply chain can move, it’s no wonder that retailers who trust too willingly in their suppliers can land up in hot water when things don’t go according to plan.

The only way to address these challenges head on is by conducting a quality audit.

Discover our factory quality audit checklist that touches on quality management, social and environmental compliance here.

An audit of your supplier’s factory is conducted to ensure that your supplier and their factory’s operations are able to produce your product to your expected levels of quality, as well as ensure compliance in your product’s destination market.

This is not the only reason though…

Carrying out audits also help to assess the risks that may be present with a particular supplier and provide direction on how you can go about managing that risk.

Ultimately, the decision to work with a particularly supplier will be up to you, but your decision will at least be based on a trusted risk assessment with a presented improvement strategy.

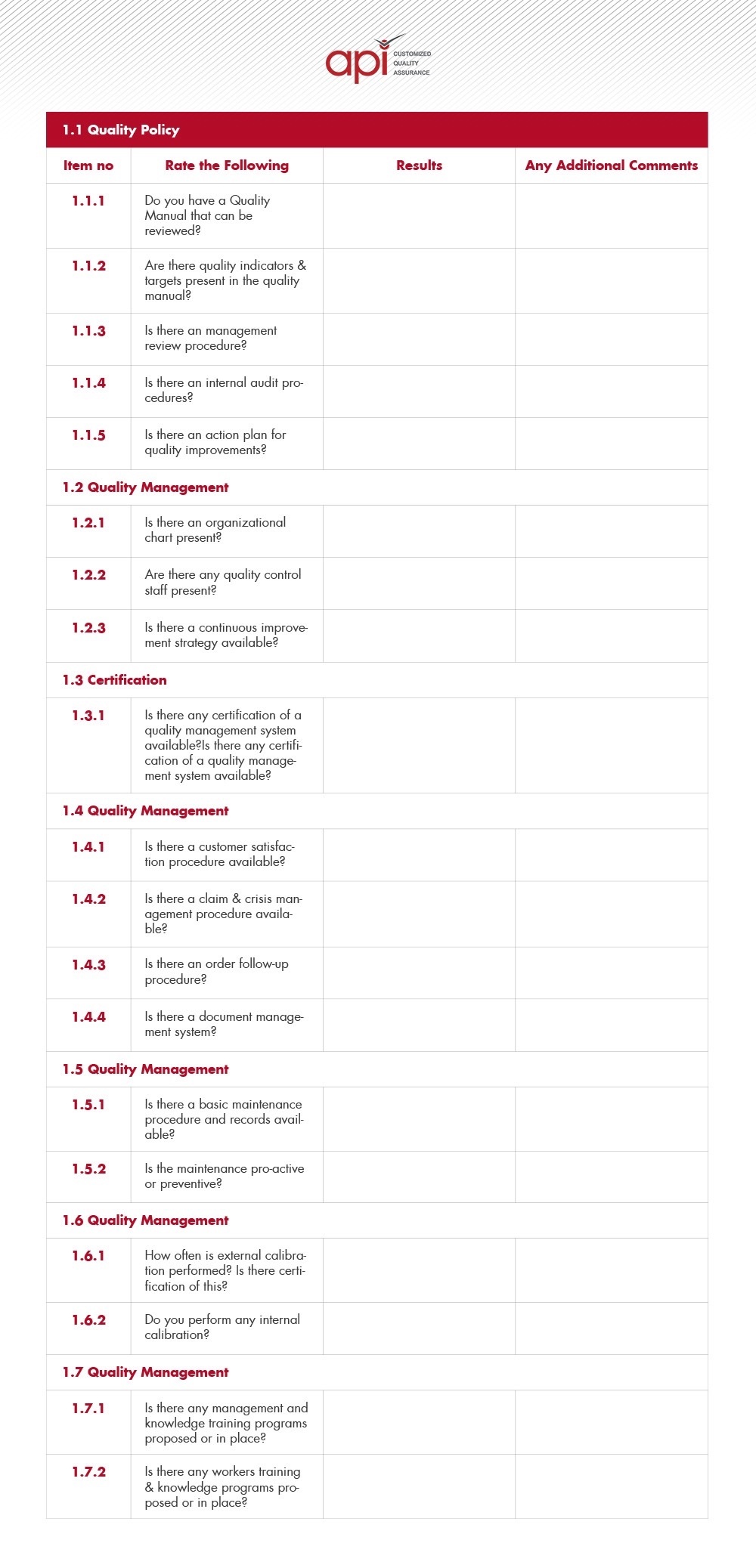

Our checklist takes you through a what a brief assessment of your supplier’s quality systems would/should look like.

We will cover 3 main sections in this checklist:

WHAT TO LOOK OUT FOR:

WHAT TO LOOK OUT FOR:

- Quality Assurance & Technical Questions

- Social / Health & Safety Questions

- Environmental Audit Questions

How Does A Quality Audit Grading System work?

For each checkpoint, the following guideline should be used; N/A – Checkpoint not available or not evaluated. 0 – Major non-conformity – absence of procedure or proof of big discrepancies in implementation – a corrective action will be designed for this checkpoint. 1 – Minor non-conformity – incomplete procedure or proof of discrepancies in implementation – a corrective action will be designed for this checkpoint. 2 – Acceptable – procedures are available and implementation is acceptable, however opportunities for improvement exist – an opportunity for improvement can be designed for this checkpoint. 3 – Good – procedure and implementation acceptable, no opportunity for improvement identified. 4 – Best Practice – factory has designed and implemented best practice of industry.Quality Assurance & Technical Questions

WHAT TO LOOK OUT FOR:

WHAT TO LOOK OUT FOR:

- Quality manual and all procedures show revision control (sign-offs & dates), history of changes

- Product quality yield data, problems and corresponding improvement actions, status of preventive/ corrective/audit results

- Strategic and tactical objectives, goals, action plans, etc.

- Analysis of field failures, inspection yields, resource needs, internal audit results, corrective action status, etc.

- Management review meetings, goal setting, performance measurement, internal audits, action plans, customer surveys

- Employee involvement/recognition program, Lean, Six Sigma, kaizen, SPC, 5-S, cost reduction programme

- Corrective actions, trend charts, meeting minutes, non-conformance frequency & cost analysis

- Management review meetings and corrective actions

- Look for use of training aids and work instructions at work stations

- Qualification records, certification history

- Records of testing, production quality records, audit records, interview workers to validate training records

- Job descriptions, job skills assessment, training records, training manuals

What if my quality assurance score is below standard?

API is able to customize its QA solutions based on your specific needs and requirements. API will provide the supplier information on how they can go about improving various things within a factory. This information will be relayed back you, the retailer, where you will gain insight into your potential supplier and their factory operations to ensure compliance across the board.SOCIAL / HEALTH & SAFETY QUESTIONS

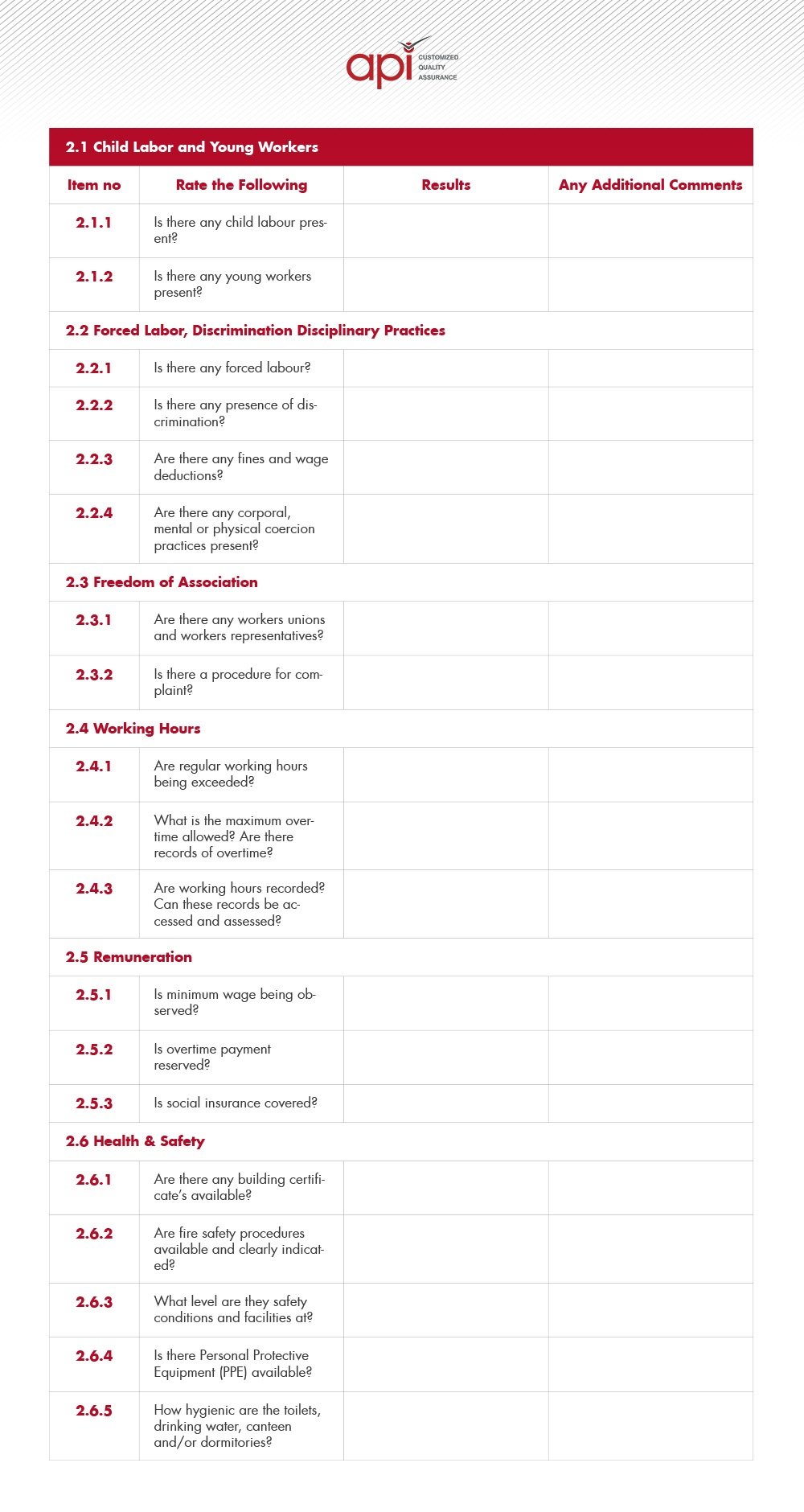

What to look out for:

- Procedure for training and communication and participation

- Emergency preparedness and response plan, monitoring and performance measurements

- Policies and procedures, health and safety trend charts, accident rate improvement history

- Safety committee or group meeting minutes, accident investigation reports, safety audit reports

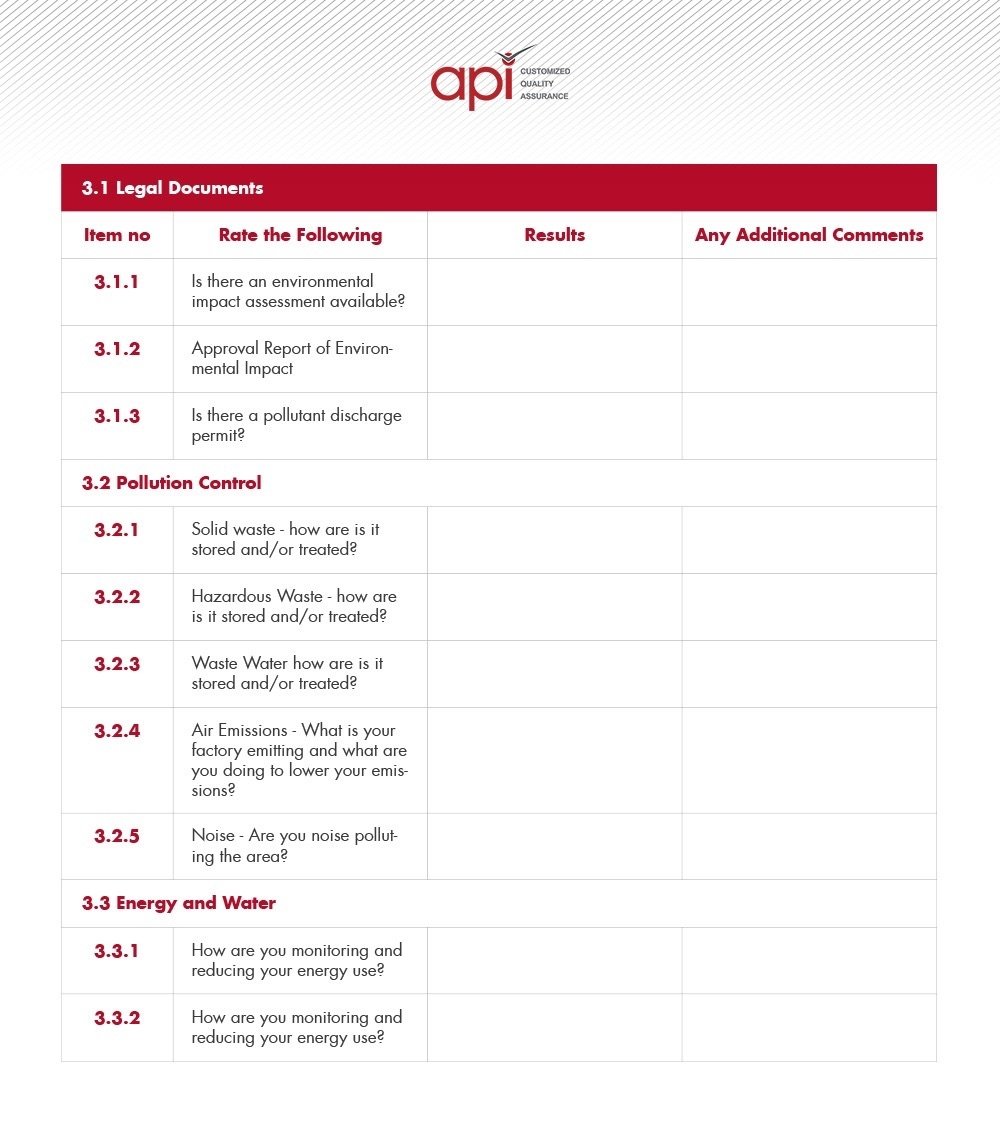

Environmental Audit Questions

What to look out for:

- Environmental policy statement document

- Records of agency/government inspection, procedures for measuring and monitoring environmentally sensitive activities

- Record of purchases, waste stream and consumption; inventory control procedures

- Records/use of; non-hazardous (RoHS/WEEE compliant) materials in production, biodegradable materials, returnable containers or packaging, recycling program, packaging materials made of recycled materials

Key Takeaways

A factory quality audit checklist allows you insight into your suppliers quality control processes and manufacturing capabilities, their strengths and weaknesses. This empowers you to strengthen those weaker processes where needed. A quality audit checklist will help ensure:- your factory’s quality systems are up to date, organized and well recorded.

- confidence in the selection of your supplier based on checklist insights.

- confidence in the quality of the product that is manufactured.

- confidence that compliance standards are actively being met by your supplier.

According to the guidelines as laid out by ISO 9001:2015, they are roughly categorized into eight sections; five of which are mandatory for the QMS of your factory;

According to the guidelines as laid out by ISO 9001:2015, they are roughly categorized into eight sections; five of which are mandatory for the QMS of your factory;

The

The  There are many concerns with regards to a situation as the above 1. The chemical usage in the toys would likely not have met international regulation. 2. Hiding violations from an auditor only aids non-compliance and illegal production processes. 3. How are these chemicals affecting factory workers? How are they stored? How are they disposed of?

There are many concerns with regards to a situation as the above 1. The chemical usage in the toys would likely not have met international regulation. 2. Hiding violations from an auditor only aids non-compliance and illegal production processes. 3. How are these chemicals affecting factory workers? How are they stored? How are they disposed of?

Many factories struggle with resources and finances, which means their money will often go into sourcing raw materials for the next production before putting money into the servicing of their machinery and equipment. This will mean that when an auditor comes to inspect the factory and its layout that the machinery is often out of calibration or filled with too much oil, which can contaminate your product and potentially places your brand in a risky position. Not ideal.

Many factories struggle with resources and finances, which means their money will often go into sourcing raw materials for the next production before putting money into the servicing of their machinery and equipment. This will mean that when an auditor comes to inspect the factory and its layout that the machinery is often out of calibration or filled with too much oil, which can contaminate your product and potentially places your brand in a risky position. Not ideal.

ation. If this is discovered during your audit process, it is recommended to rather find a different supplier. There are no grounds where this is acceptable.

Hazardous working conditions – Hazardous and unsafe working conditions are not unheard of in many third world factory’s across the globe and are often the cause of factory technical audit failure. Things like faulty Personal Protective Equipment (PPE), expired fire extinguishers, no clearly marked exit signs, exits not in working order, machinery that is in need of calibration or lack of safety gear found on heavy machinery can lead to audit failure. These safety violations are easy enough for your supplier to address and solve, so bear this in mind upon receiving audit results as you will often need to factor in corrective time for your supplier.

ation. If this is discovered during your audit process, it is recommended to rather find a different supplier. There are no grounds where this is acceptable.

Hazardous working conditions – Hazardous and unsafe working conditions are not unheard of in many third world factory’s across the globe and are often the cause of factory technical audit failure. Things like faulty Personal Protective Equipment (PPE), expired fire extinguishers, no clearly marked exit signs, exits not in working order, machinery that is in need of calibration or lack of safety gear found on heavy machinery can lead to audit failure. These safety violations are easy enough for your supplier to address and solve, so bear this in mind upon receiving audit results as you will often need to factor in corrective time for your supplier.

Let’s take a look at how this could play out;

Let’s take a look at how this could play out;